Monopticks

Fiber Optic Generator Core Monitoring

There is a better way to measure temperature and dynamic strain on the generator.

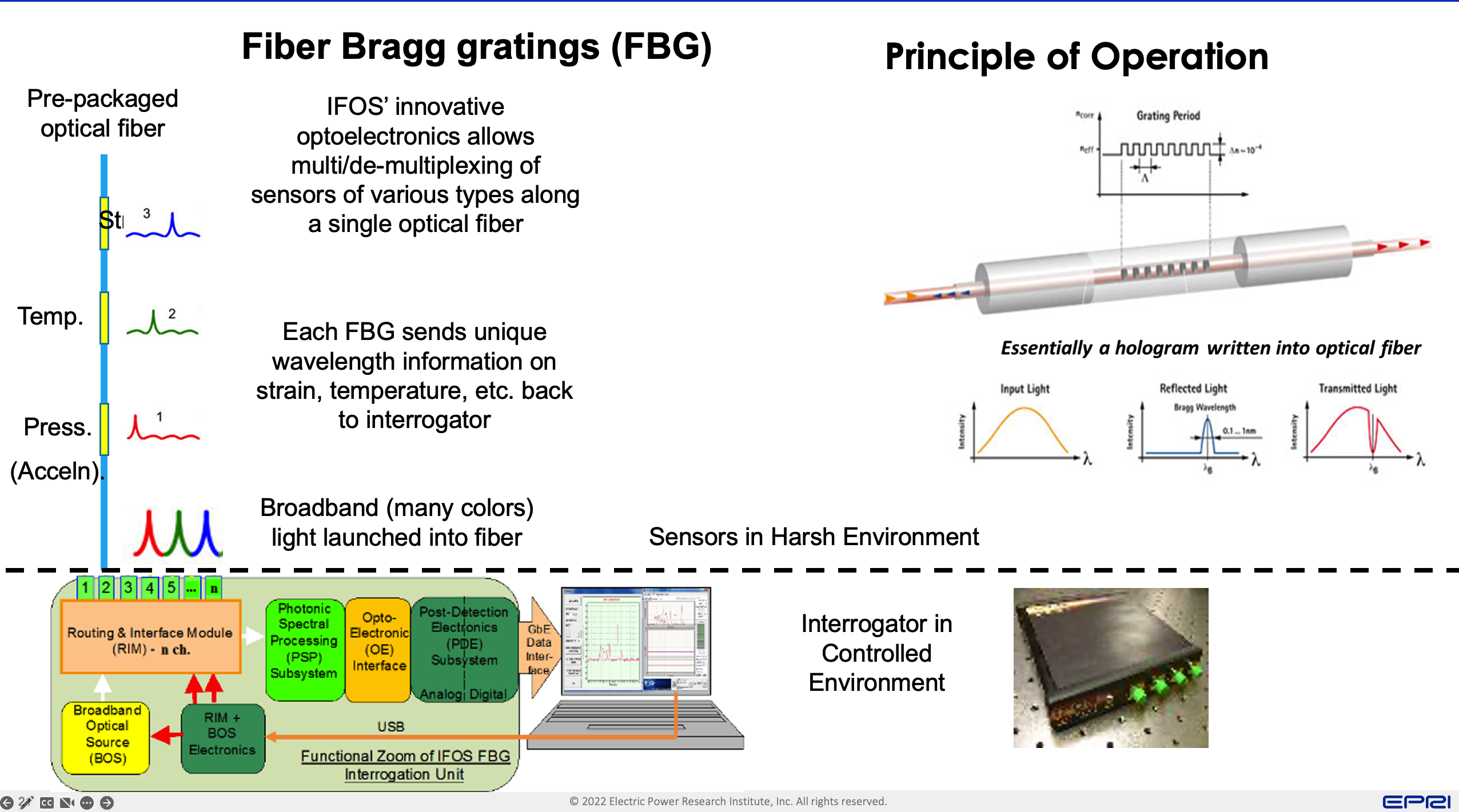

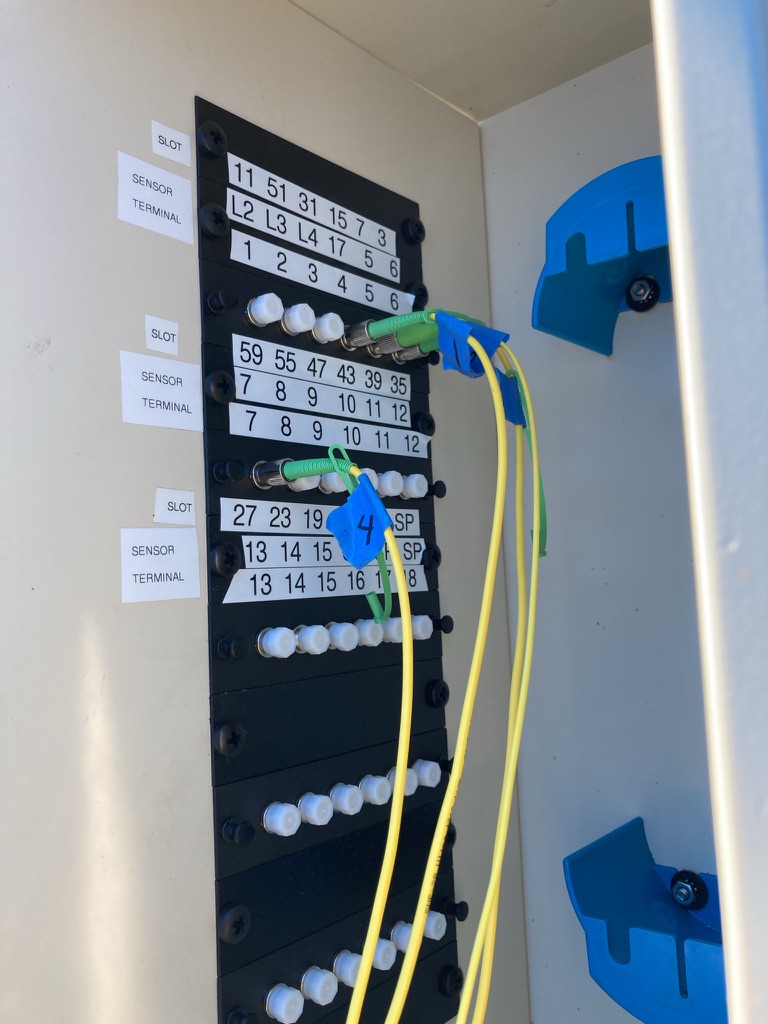

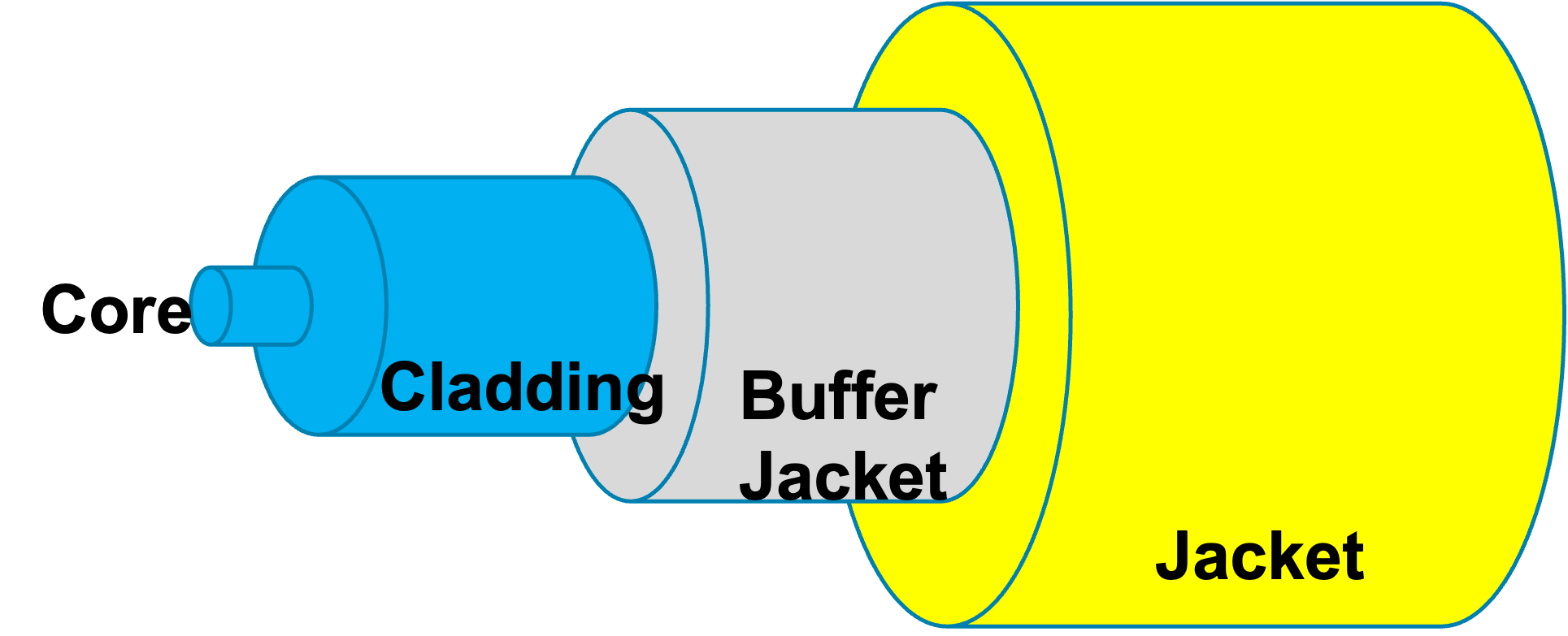

The Monopticks system uses fibers laser-printed with test points called Fiber-Bragg Gratings (FBGs) Each test point in a given fiber only reflects certain wavelengths. Other wavelengths pass through, allowing multiple points to be written on each fiber. The fibers are then read with a laser interrogator, giving both static and dynamic strain readings for each point.

One system, two readings. Temperature and dynamic strain.

By reading static strain, we can calculate temperature, much like the earlier system. By reading dynamic strain, we get coil motion readings. So, using this technology, called Wavelength Domain Multiplexing (WDM), we can glean both temperature and coil motion at each sensing point. By bonding the sensing fiber to a piece of specially machined wedge filler, We get both coil temp and coil motion signals.

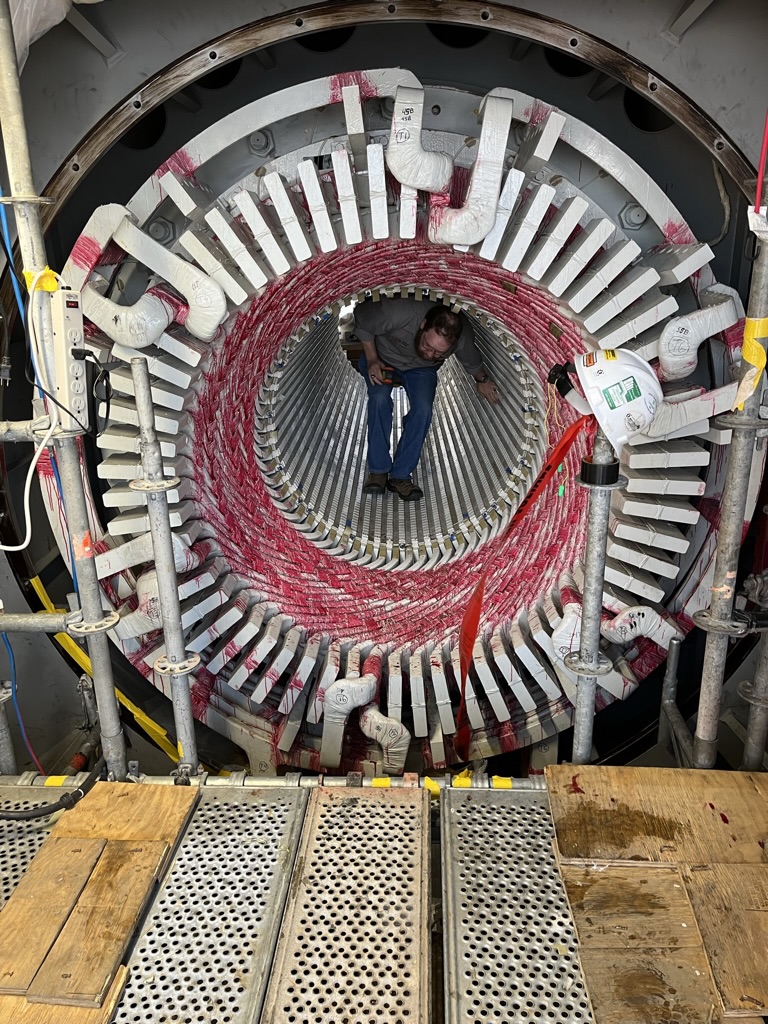

Installed under the wedges. Easy installation.

System is installed under new wedges. By testing multiple times over a time interval, deterioration of wedge package can be trended.

Fiber Optic advantages. Temperature and dynamic strain.

Low Size, Weight and Power consumption (SWaP) + High Performance. Electromagnetic Interference (EMI) immune and Noise free, Electrically passive, Long transmission, remote access, High durability, and Small enough to be integrated into composite structures & smart tools. Easy installation and less labor than comparable electronics sensors, and reduces cost due to telecom sector investments.

FBG background information.

- Highly accurate, discrete, multiplexible

- Dynamic, discrete, multi-point Temperature, Strain, Displacement

- Based on wavelength shift detection: sub-picometer resolution sub-microstrain resolution